Olsen Engineering UK has launched the Bison SANIMotor range of stainless steel gearmotors that meets the IP69K extreme washdown rating. SANIMotor has aroused interest in the international OEM food packaging industry from as far afield as Dubai, following successful implementation in the US.

SANIMotor gearmotors are designed to meet the IP69K extreme washdown rating established by the European IEC for equipment exposed to temperature extremes, constantly wet environments, and the use of harsh cleaning agents. Electrical components are encapsulated in thermally conductive epoxy resin, allowing use at up to 40°C (104°F) ambient temperature and higher temperatures with D rating.

Encapsulation optimises heat conduction within the motor, allowing totally enclosed non-ventilated (TENV) operation, VSD / Inverter compatible based on a 10:1 turn down ratio for constant operation. Output shaft sealing is achieved with a two part rotor-stator style seal, providing three sealing surfaces. Electrical termination is provided by an IP69K rated stainless steel, modular, multi-pin power connector. The gear motors can be mounted in an orientation and have high side load ratings, fully tested.

The three-phase 230V inverter-duty SANIMotor range employs Bison’s Verdant Duty design for increased energy efficiency. It is available in two frame sizes; 88.4 and 127mm, each of which is mated to seven standard gearing packages, offering fixed output speeds from 345RPM to 8RPM at rated torque from 0.8 to 56.5 N-m. The SANIMotor range are available as part of Bison’s In-Stock - Instant Ship (ISIS) program.

“SANIMotor is ideally suited for food, chemical, medical and pharmaceutical processing applications,” explained Piers Olsen of Olsen Engineering UK. “It also finds a home in foodservice equipment, packaging machinery, factory automation, conveying, car washing and a wide variety of demanding applications where gearmotors are exposed to harsh environments or frequent washdowns.”

The SANIMotor has had proven success in the US at Eaglestone, a custom conveyor and equipment manufacturer specialising in food processing and packaging machinery. With the intention of reducing the accumulation of food borne bacteria, Eaglestone designed a new stainless steel conveyor for baked and frozen goods, incorporating the SANIMotor.

Once installed, the SANIMotor performed well in the harsh environment created by the wash-down process and provided reliable operation of the transfer conveyor without any maintenance issues. Units are sealed for life with H1 food grade grease.

“We chose SANIMotor for its ability to stand up to the conditions of an extreme wash-down environment, and Bison exceeded our expectations,” explained Carmen Sammauro, Eaglestone’s President.

SANIMotor features a smooth outer exterior, encased in 304 grade stainless steel to ensure clean, hygienic food processing while enduring moisture, heat and harsh cleaning solvents.

Thursday 22 August 2013

Tuesday 4 June 2013

Actuation bats for defence at DSEI 2013

|

| Demonstrating Olsen's proficiency in applying Exlar electric actuation design |

The Defence & Security Equipment International (DSEI) is the world’s largest land, sea and air biennial defence and security exhibition, bringing together senior international trade and military experts from across the entire supply chain.

“The MoD shows an inclination to move away from hydraulic to electric actuation, and manufacturing companies like BAE now see the future in all-electric actuation because of reduced fire risk oil, leaks and reduced maintenance,” says Piers Olsen, director of Olsen Engineering UK.

“Integrated all-electric designs significantly improve efficiency, effectiveness and survivability. Exlar electromechanical actuation has been applied to defence and aerospace designs for munitions handling, weapons positioning, ammunition magazine control, valve control, hatch opening and closing, tank turret control and gun and camera mounting.”

Electric actuation makes military vehicles, crafts and vessels less vulnerable in combat. In aircrafts for example, it does away with hydraulic lines in fuselage and wing box, has lighter weight, and facilitates smaller aircraft and unmanned aircraft design. Increased efficiency is another major benefit as there is only one energy conversion process. The trend towards all-electric design is fuelling this development.

On ships the prime mover, such as a fuel-burning turbine, will convert the energy directly to electricity for powering motors and actuators around the vessel, instead of conventional mechanical power transmission, including the motors driving the propellers. Olsen Actuation predicts that soon all the hatches, valves and firing mechanisms will be electrically powered as well.

“High power electric actuation systems are being proposed on many new aircraft,” Olsen concludes. “Most new aircraft designs now use electrically actuated ball screws driven by electric motors for the spoilers, some flaps and flight controls instead of hydraulic motors.

Wednesday 17 April 2013

Daresbury offices for actuator specialist

|

| Sci-Tech Daresbury |

The new space gives Olsen the means to take advantage of networking opportunities with other science and technology companies from within the campus, as well as being able to use the vast array of multi-media conference facilities.

Sci-Tech Daresbury is one of two National Science and Innovation Campuses established in 2006. In December 2010 a new joint-venture company was created to spearhead the long-term development of the Campus. Partners in the joint venture are property developer and investor Langtree, the Science and Technology Facilities Council (STFC), and Halton Borough Council.

“The whole philosophy around the Sci-Tech Daresbury is that they don’t just let anybody in - you have to be a fast-growing technology company,” explained Piers Olsen, managing director of Olsen Engineering.

“There are regular networking events at the campus and it is all about the common goal of accelerated growth. They encourage the 120 companies on campus to trade with each other and use each others’ resources. We have access to many technology companies with the possibility to outsource design and manufacture; several could even become good customers.

“There is a broad range of facilities available on campus, including ten different levels of meeting and conference rooms kitted with the latest multi-media technology, the largest of which is a 156-person lecture theatre. Other on-site facilities include a Starbucks café, a restaurant and a gym,” continued Olsen.

“STFC is based here too, which funds and supports science and technology in a broad cross section of the UK research community. STFC has close links to the European Council for Nuclear Research (CERN), so we get access to all the online tendering for new projects within CERN. This gives us an exclusive range of opportunities and we have already registered for a project in Sweden.

“STFC pioneered the frontier machine for light source synchrotrons, helping develop the ideas for CERN. Today globally installed machines are valued at more than £60 billion. The site boasts the UK’s largest supercomputer, HPCx, for developing applications. The site is also very scenic, bordered with oldest canal in the world. Daresbury STFC is also developing the largest radio telescope in the world, and the Nuclear Structure Facility has the world’s largest Van de Generator.”

John Leake, business development manager at Sci-Tech Daresbury, said: “ We're delighted to welcome a business of Olsen Engineering’s calibre to the growing cluster of high-growth, high-tech businesses on the campus, and I'm sure that the facilities and community at Sci-Tech Daresbury will contribute to the company’s continuing success.”

Labels:

actuators,

Daresbury,

Olsen Engineering

Location:

Caersws, Powys SY17 5NA, UK

Wednesday 20 March 2013

Larger frame Exlar K90 actuator offers inline or parallel motor coupling

|

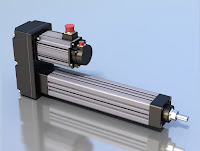

| The Exlar K90 actuator |

Olsen Engineering has launched the Exlar K90, a larger 90mm frame version of the K60 low cost electric “rolled” linear actuator, which employs satellite roller screw technology. The K series offers flexibility of motor and servo amplifier choice. Also in the IM/IX series variation there option of integral inline planetary gear reduction up to 10:1.

Ideal for low cost food packaging applications where users may want to use their own servo motors like Siemens, Rockwell, Baldor or similar, Exlar’s K series provides long life and is available as standard in an IP65-rated ingress protected enclosure. Roller screw linear actuators provide an efficient modern alternative to hydraulic or pneumatic units in a much more compact, low maintenance format, without the contamination or noise problems. The K series offers the option of two grades of planetary roller screws “rolled satellite M and X grades” along with an option for an ACME screw.

A roller screw is a mechanism for converting rotary torque into linear motion, in a similar manner to acme screws or ball screws, but the differentiating factor is that roller screws can carry heavy loads for thousands of hours in the most arduous conditions. This makes roller screws the ideal choice for demanding, continuous-duty applications, or giving extremely long life in general purpose applications. Olsen Engineering has already won a large OEM customer for the newly launched K90 who realised the advantage a dynamic load rating of 51kN, with low capital investment.

“The K90 drive motor can either be coupled inline or in parallel mount using a 1:1, 1.5:1, or 2:1 ratio belt or any custom ratio belts,” said Piers Olsen, sales and marketing director for industrial automation at Olsen Engineering UK. “We request a drawing of the drive motor to be used and then we design and manufacture the adaptor plate and housing to suit the motor, coupling and belt to be used.”

A recent technical release from Exlar states that since their belts are designed for four times the peak rating of the actuator they are extremely reliable and more efficient than a gear drive system – see link:

http://www.consultolsen.com/press_downloads/TechNoteBeltsvsGears.pdf

Olsen adds: “The K90 has internal anti-rotate sliders in the form of a precision nylon coupling running on linear guides inside the frame designed to protect the roller screw mechanism in the event of 1.25 times the peak recommended input torque. It has a comprehensive choice of coating options including a smooth food-grade extrusion, white epoxy FDA approved, electroless nickel salt water rated and Type III hard coat outdoor use, and comes as standard with black anodised aluminium end caps.”

The main rod material is stainless steel tipped with electroless nickel-plating suitable for food industry and washdown locations, with full stainless steel option available. While the K60 handles a maximum force of 6kN at a speed of 420mm per second or 3kN at 833mm per second based on a 5,000 rpm input speed, it is possible to over-speed at 7,500 rpm up to 400mm travel, and also comes in a 950mm travel version. A non back-driving acme screw option provides a low cost solution for low-duty applications, without the need for fail safe braked motor option in high load vertical installations.

The newly released K90 handles force to 15.6kN at 250mm per second based on a 3,000 rpm input, and 7.8kN at 500mm per second, and again it is possible to over-speed to 5,200 rpm up to 800mm.

“You have to be mindful of over-speeding at longer travel lengths, because this can result in a torsional whipping effect as the actuator accelerates and decelerates,” continues Olsen. “It is possible to use a 2:1 belt to reduce the motor size. Also the maximum radial loading reduces at longer actuator travel lengths (up to 2m option available).

“If the inline coupling option is selected, we have designed a bellows compression coupling to connect the drive motor to the actuator. These low-friction units incorporate a G9-rated 0.2mm backlash in the M series and 0.1mm in the X series and 200µm/1000mm lead accuracy, operating at a temperature of up to 80 degrees centigrade.”

Mounting options include rear-clevis mount, front or rear flange mount, front or rear angle mount, foot mount and trunnion mount. Because the aluminium extrusion has grooves in all four sides of the frame, it is possible to slide the trunnion and foot mounts to any position as needed for the application. It is also possible to mount it directly on the front face plate of the actuator including ISO63 and other pneumatic cylinder standard dimensions for ease of retrofitting.

“You can have limit switch options, and we supply the clevis pins and the front spherical rod eyes,” concludes Olsen. “We can supply Exlar SLM rotary servo motors with connectors to match the drive manufacturer’s standard cables and with rear clevis for inline mounting for inline filling applications, which is quite unique. Also a front protective bellows option is useful in dirty environment to offer additional protection to the front seal assembly.

“The whole philosophy of the K series is to design and produce a low cost actuator to compete with ball screw mechanisms while still providing two to three times the travel life, together with advantages such as a preloaded angular zero-backlash bearing which is heat-shrunk rather than glued, IP65 as a standard, also Food Grade, Cleanroom and low temperature grease options for -40?C operation, lower noise, faster accelerations and reduced risk of Brunnelling on pressing & sealing applications.”

Exlar carry stocks of all common travel lengths so standard production times are 3 weeks. For OEMs, Olsen also can carry local stocks of preconfigured part numbers - all part of the service.

Labels:

actuators,

Exlar,

K60,

K90,

Olsen Engineering

Location:

Caersws, Powys SY17 5NA, UK

Subscribe to:

Posts (Atom)